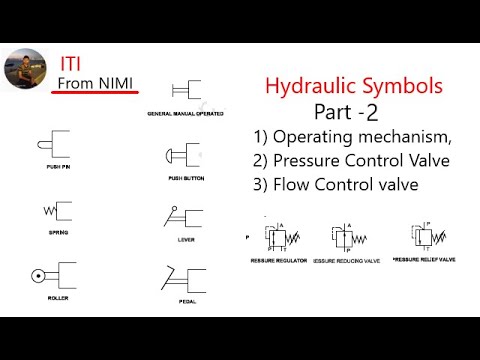

Basic Types by operating principle. Ports in a valves body lead into a section so that a spools situation determines which ports are open and which ones are closed. The compensator spool is spring loaded such that the resultant force from the spring, the hydraulic load and the incoming fluid will position it to open the inlet to just the right size to maintain a constant volumetric flow rate even with pressure drops in the system. When the system pressure surges that it becomes greater than the force from the spring, the fluid will unseat the ball such that it opens the flow to let excess fluid flow out until the system pressure is in the accepted range. There is pressure loss because of high restriction of the flow of fluid. Valves fluctuate generally in frame and application. These three types of valves are smooth in operation and performance and work as a whole system. Download this article in .PDF format. Pressure control valves regulate the pressure of the fluid passing through the pipe or tubing by releasing the excess pressure. fail closed vs. fail opened) and the choice plays a major role is sizing an actuator. Any valves fitted with automatic actuatorscould be considered control valves, as they presumably would be tied in with remote process controllers. Hydraulic system uses many valves to control the flow of fluids, hydraulic valves regulates flow by cutting off, diverting, providing an overflow relief, and preventing reverse flow. The phrase control valve is sometimes used to describe the valves used in hydraulic and pneumatic fluid power systems to actuate a ram, for example. Lift-type check valves are similarly constructed as globe valves and use a ball or piston, often backed by a spring that opens under a specified pressure but closes as the pressure decreases, thus preventing backflow. And when the cylinder extends, the valve has to open its secondary port that is connected to the reservoir. Pneumatic & Hydraulic Company is a premier supplier of pneumatics, hydraulics, filtration and motion control products. Two operating ports are connected to an actuating unit. This means they have to be constructed from materials that can withstand these high pressures. All Rights Reserved. Spring action automatically turns the spool to the normal offset position when shifter force is released. Valves are characterized as gadgets to control or manage the beginning, end, course and furthermore the weight or rate of the stream of liquid under strain which is conveyed by a blower or vacuum pump or is put away in a vessel. Disc valves are used in food, pharmaceutical, and dairy industries to for shut-off service of liquid, powder, or food slurries where sanitation is critical. They are not generally used for proportional flow control. For more information watch this video about types of valves. In the hydraulics market, you can find different types of hydraulic valves by different manufacturers designed to do different things in different applications. Types of Hydraulic Valves. Because of the high number of turns required to close a needle valve, they are not ideally suited for use in shut- off service applications. 5-Gate valve mainly for on/off control, with low pressure drop. Ball valvesare used practically anywhere a fluid flow must be shut off, from a compressed-air line to a high-pressure, hydraulic system. Valves fitted with such actuators are sometimes called control or flow controlvalves in that with automatic actuation they can be integrated into control loops used for process automation. We update our inventory daily, tracking levels at each of our warehouses. They can also change into intermediate states to control an actuators acceleration, speed or direction. They can act as many valve types in a single cartridge. Faucet Valves are used for controlling fluid flow into basins or sinks and typically lack outlet connections, though some are equipped with threads for connecting hose, often called a hose bibb or spigot. Generally, a valve needs to fit in the space between fixed pipes so this dimension can be critical if modifications to existing piping are undesirable and are to be avoided. A disc valve consists of a round flat plate mounted to the end of a stem that enters the pipe at 45 degrees to the pipe longitudinal axis. Valves can be categorized into the following types, based on their operating mechanism. They are used extensively in pneumatic systems as well. Some 3-way valves have a 3rd position that blocks flow in all ports. Check valves are 2-port valves. Wedges can take on a variety of design alternatives that reduce or accommodate wear of the sealing surfaces. Working Principle, Types & Applications, What are Coaxial Valves? These two right-angle turns that the fluid must make through the valve account for the designs relatively high head losses. A float valve is used primarily for maintaining fluid in a tank at a specific level. Ball valve mechanisms are used as Switches to shut out or open the flow. Globe valves are used for shut-off and regulating, and are used in wastewater plants, food processing facilities, and process plants, for example. Electrical/electronic actuation_Electrical/electronic actuation needs solenoids that convert electrical signals of current supplied to the solenoid coil into a plungers mechanical action that makes either rotary or linear movement. Image credit: Yuthtana artkla/Shutterstock.com. Some valves are so common that they are grouped by function, for example, boiler feedwaterand blowdown controlvalves, faucet valves, float valves, double block and bleed valves, HVAC zone valves, or floor drain check valves. The valve employs solenoids denoted by X and Y in the picture above. Valves are available in the smaller sizes in a host of plastics and find use in many laboratory applications. In this example, the pressure compensator is a compensator spool. This variation comes because sometimes the temperature of operation may rise such that set tolerances in orifices will become inaccurate. This is where a small relief valve (depicted as a rod with piston above) is moved so that it actuates the main relief valve (depicted with spring above). Since the pressurized areas on both sides of the poppet are equal, the spring exerted a fixed reduction. When the main function is satisfied, the pressure in the primary circuit will rise and then it is sensed in the pressure-sensing channel. This valve operates by balancing the force applied by the pressure in the main circuit against the sum of the forces applied by secondary circuit pressure and the spring. There are many types of hydraulic valves available in the industry. WebDirect hydraulic control is the simplest of the control methods. Key specifications include valve type, actuator type, port connections, valve size, and the material that make up the valve body, which includes its seat, seal, lining, and stem packing. Solenoid action shifts the integral pilot spool and directs the pilot flow to move the main spool. 10- Piston valve for regulating fluids that carry solids in suspension. Either Controlling pressure, flow rate or changing direction. Gate valves can use wedge-shaped plugs or parallel plates. The land functions to block the flow, while the groove functions to allow flow through the valve. For flow regulating, globe and butterfly valves are preferred choices, with globe valves being especially common. Key specifications include the intended application, head and stem diameter, and the material. The function of a directional control valve is determined by the number of working ports and the number of spool positions. The principle mechanism is the science concept that if employed, the flow control will be varied. Retract liquid is introduced from the hydraulic pump to the rod end of the cylinder, which in turn causes it to retract. Valve standards are almost too numerous to list but the reader is directed to various standards organizations such as ASME, ANSI, and API for their comprehensive collections of pipeline and valve standards. Volumetric flow rate we measure volume per unit time in the units such as the cc/min or in3/sec. 6- Globe valve good for regulating flow. This difference in the surface area will mean that a rise in the system fluid pressure will be multiplied on the smaller surface area (pressure is inversely proportional to the area). Air logic valves are applied to pneumatic systems as e-stops, pilot valves, one-shot valves, etc. They can also be used as throttle valves when you turn them only partially but they are not well recommended for throttling. Compression fittings also apply mainly to small valves used with tubing of copper, plastic, etc. The pressure line is connected to a pressure port. 1. As the name suggests, directional control valves are used to direct the flow of fluid through the system. These valves can control the start, stop, pause, and change in direction of flow of a pressure medium. Company. Temperature compensators are installed to cater to these variations. Hydraulic valves are generally controlled automatically on stationary industrial machinery and manually on mobile machines. This fluid flow causes a drop in the pressure across the spool. Valve actuation depends on the valve type. Pressure: The valve has to be able to endure the maximum pressure required for your application. In such scenarios, sequence valves can be utilized to actuate the cylinders in the required order. G is an inlet port, (D) is the Bonnet, and (E) is the valve housing. Valves are mechanical or electro-mechanical devices that are used to control the movement of liquids, gases, powders, etc. But unlike metal swing or flap check valves, rubber duckbill check valves are pretty reliable. The various methods of flow control used by hydraulic valves include: Throttling flow control is when the size of the path of the fluid is adjusted so that one can vary the flow rate. This is done either by making sure the system pressure does not exceed a certain set point. Relief valves chip in to help safeguard to prevent machine damage and operator damage. Piston Valves are mechanical devices used to control fluid flow through a pipe. WebDifferent Types Of Valves With PDF File. The most common designs comprise a swing or flap. WebValves can be categorized into the following types, based on their operating mechanism: Ball valve, for onoff control without pressure drop. In hydraulic circuits with more than one actuator, it is common to drive the actuators, such as the hydraulic cylinders, in a definite order or sequence. It consists of a drilled hole in what acts as a passage on an otherwise blocked fluid passage. As the handle is turned, the plunger will move up and down the threads (C) while the Locknut (B) will stop it from fully unscrewing. Christmas tree valvesare used primarily in the oil and gas well application and are typically mounted to the head of the well for shutoff or controlling the flow of the media. Relief valves are used on pneumatic compressors, on gas lines, and in cryogenic systems in short, anyplace where over-or under-pressure conditions can occur. decreasing the flow rate reduces their driving speed and vice versa. Flow is regulated by inserting or withdrawing a tapered stem into or out of a similarly tapered orifice, creating a very precise way of adjusting fluid flow through the orifice. There are many possibilities for the actuator mechanism, including pilot, electrical/electronic, mechanical actuation. The three most common types of hydraulic valves are: directional control valves, pressure control valves and flow control valves. Actuators and Controls 7.1 Spring 7.2 Manual (Use as general symbol without indication of specific type; i.e., foot, hand, leg, arm.) Safety valves are made in 2 forms:

10+ million models from leading OEMs, compatible with all major CAD software systems. Media may include, water, chemicals, gases, oil, steam, or other similar fluids.  In figure A, the spool is in a position that port P is free to port A, and port B is free to port T. Ports A and B are joined to the ports of the cylinder, flowing through port P, and make the piston of the cylinder to travel to the right. The function of the Hydraulic Control Valve, Pneumatic actuators Suppliers and Companies, Regulating & Pressure Reducing Valve Suppliers and Companies, Control Valve Types101: Different Classifications, Advantage and Disadvantages, Types of Pneumatic Valves: Specifications and Working Principles, Globe valve types: basic types plus bold pros and cons, Thermal Expansion Valves: Everything You Need To Know, 6 Main Types of Expansion Valves: an Easy to Understand Guide, Strainer Valve: a basic guide to know it better, Working Principle of Control Valve with Diagram, Difference Between Gate Valve and Globe Valve, Everything You Need To Know About Check Valve Function, 10 Types of Water Valves: The 2022 Ultimate Guide, Gate Valve vs Butterfly Valve: Comprehensive Guide in 2022, Best Check Valve for Sump Pump: 9 of the Best Models. WebHydraulic Control Valves Valves can be classified according to their functions to three main types 1- Pressure Control Valves 2- Flow Control Valves 3- Directional Control Valves Pressure Control Valves It can be used to limit the maximum pressure (a relief valve), to set a back pressure (a They include relief, reducing, sequence, counterbalance, and unloading valves. Directional control valves have three functions: These functions typically operate in combinations. In the smaller sizes, solenoid valves function as control valves. Pressure rating: this is the maximum pressure that the valve will perform in. It incorporates a flipped disk to either open or close a pathway. Then there are spring and ball check valves. Used in pharmaceutical applications. In general, these hydraulic valves may be described as being of three main varieties which are: Hydraulic flow control valves are used to regulate the flow volume of passing fluid in hydraulic systems.

In figure A, the spool is in a position that port P is free to port A, and port B is free to port T. Ports A and B are joined to the ports of the cylinder, flowing through port P, and make the piston of the cylinder to travel to the right. The function of the Hydraulic Control Valve, Pneumatic actuators Suppliers and Companies, Regulating & Pressure Reducing Valve Suppliers and Companies, Control Valve Types101: Different Classifications, Advantage and Disadvantages, Types of Pneumatic Valves: Specifications and Working Principles, Globe valve types: basic types plus bold pros and cons, Thermal Expansion Valves: Everything You Need To Know, 6 Main Types of Expansion Valves: an Easy to Understand Guide, Strainer Valve: a basic guide to know it better, Working Principle of Control Valve with Diagram, Difference Between Gate Valve and Globe Valve, Everything You Need To Know About Check Valve Function, 10 Types of Water Valves: The 2022 Ultimate Guide, Gate Valve vs Butterfly Valve: Comprehensive Guide in 2022, Best Check Valve for Sump Pump: 9 of the Best Models. WebHydraulic Control Valves Valves can be classified according to their functions to three main types 1- Pressure Control Valves 2- Flow Control Valves 3- Directional Control Valves Pressure Control Valves It can be used to limit the maximum pressure (a relief valve), to set a back pressure (a They include relief, reducing, sequence, counterbalance, and unloading valves. Directional control valves have three functions: These functions typically operate in combinations. In the smaller sizes, solenoid valves function as control valves. Pressure rating: this is the maximum pressure that the valve will perform in. It incorporates a flipped disk to either open or close a pathway. Then there are spring and ball check valves. Used in pharmaceutical applications. In general, these hydraulic valves may be described as being of three main varieties which are: Hydraulic flow control valves are used to regulate the flow volume of passing fluid in hydraulic systems.  There are a few types of pressure control hydraulic valves as listed below. There is a volumetric flow rate which is expressed as mm3/sec. They are available in several materials and types depending on the application which may include automobiles, trucks, motorcycles, etc. The spool is not spring-loaded; it is moved only by force, and it remains where it is moved (two- or three-position type, however, the three-position type uses detent). Can be used as both pressure valve and vacuum safety valve. A double acting actuator needs a 4-way valve. When flow is no longer required in the low-pressure circuit during a portion of the cycle, the main valve closes. The advantage of rising-stem valves is that they permit easy visualization as to whether a valve is open or closed. There is also a mass flow rate measured in kg/sec, usually used to compute forces of inertia when decelerating or accelerating. are usually sized based on the valve size. Our range includes pressure relief valves in different mounting styles and for a variety of application areas: industrial as well as mobile, for the use in hydraulic and pneumatic systems, for fluid and gas handling, process In a hydraulic system, these valves are used to maintain or adjust the flow rate of the hydraulic fluid. Required fields are marked *. A safety valve is one of the types of pressure relief valve. Air valves such as this are used in automated machinery of all kinds to operate cylinders, rotary devices, and end-of-arm tooling, for example. The term poppet also describes a kind of check valve. They transfer fluid between the components of the hydraulic system. Safety valves can be seen mostly in air and stream services. This pressure reducing valve restricts the pressure in the secondary circuit (the circuit connected to the outlet) without paying heed to the main circuits pressure changes. A surge control valve is a kind of relief valve intended to reduce damage to hydraulic systems from a phenomenon known as a hydraulic surge. To escape this, a bleed passage to the reservoir keeps it opened slightly, avoiding a rise in downstream pressure above the valve setting. Sometimes control valves that are actuated with pneumatic diaphragms are incorrectly called diaphragm valves. The reader is cautioned to make this distinction. An important value to note in check valves is the cracking pressure, which is the minimum upstream pressure at which the valve will operate. Other valve types usually introduce some loss in the valve owing to the need to place the components of the valve, actuating shafts, etc. The counter-balance valve creates dynamic control within the system and the sequence valve, detects the extreme pressure. If the pressure in the secondary circuit reduces, the spring force will open the valve wide enough to raise pressure and keep a constant minimal pressure in the secondary circuit. 6- Safety valve or relief valve: operates automatically at a set pressure to correct a potentially dangerous situation, typically over-pressure. Butterfly or double doorcheck valves use two half-circle gates or wafers that are hinged at the centerline of the valve port and open downstream in the direction of flow. Ball valves can be designed so that friction loss through an open valve is no greater than what would be encountered in a like diameter pipe (also making them piggable in some cases). They all have a specific function in the hydraulic system and their names are self-explanatory. Hydraulic fluid type: this will mean you have to choose material of the valve that works well with your chosen hydraulic oil. A common adjustable flow control valve is a priority valve. Normally, the check valve closes due to the force from the action of the spring force. (Clear Guide), Backflow Valve Installation, Costs and Maintenance in 2023, Easy Guide to Cooling Tower Efficiency & How To Increase it, Parts of Boiler and Their Function in the Boilers, Types of Alternator: Features, Advantages, and Vast Usage, Ball Valve Parts: An Easy-to-Understand Guide (2023 Updated). Key specifications include actuator type, number of ports, materials of construction, switching speed, port thread size, pressure ratings, and input voltage. plug valve gate valve. This article will take an in-depth look at hydraulic valves and their advantages. The spool is a pilot-operated, pressure-reducing valve that has balanced hydraulic pressures from downstream pressure at both ends. Other flow control elements in these valves may be poppets or plungers. And for these fluids, a ball valve is a better choice owing to the uninterrupted path it presents to the fluid. Typically they are actuated with a lever which provides a visual indication of the valve status. When a direct acting valve is a normally closed one, the force exerted by the spring will be greater than that of the system. We are available for emergency service 24/7/365. They can relieve internal pressure as well as external pressure caused by vacuum formation within a tank, for example. Directional control valves are third on our list of main hydraulic valve classification. Ideal for quick shut-off, since a 90 turn completely shuts-off, compared to multiple 360 turns for other manual valves. True union refers to the connections on a valve body which allows it to be inserted in a pipeline without moving the pipes apart. Gate Valves are used mainly for blocking fluid flow and are less likely to be employed for flow regulation. The needle pin valve is used to control flow rates with high accuracy in low pressure applications. Return flow from the cylinder moves through ports B and T. In figure B, port P is free to port B, and the piston travels to the left. They are used primarily by the oil and gas industries as a means of isolating sections of a pipeline. In an open valve, liquid streams toward a path from higher strain to bring down weight. The spring can also be adjusted in length and thus the cracking pressure can be adjusted on these valves. Sequence valves are normally closed and 2-way valves. This frequently happens through an orifice in the spool, then through the spring chamber, and finally to the reservoir. ). Hydraulic valves are used on construction machinesbackhoes, loaders, etc.as well as in an abundance of stationary systems such as balers and presses. However, a basic flow control valve has an opening that can be changed to increase or decrease the flow rate. Slide a flat, cylindrical, or spherical surface across the orifice. So any mechanism that will vary the cross-sectional area across the valve will effectively vary the flow rate. WebHydraulic circuits can be comprised of an infinite combination of cylinders, motors, valves, pumps and other equipment connected via hydraulic pipes and tubes. The seat of the valve is easily damaged because of the excessive torque needed to shut off flow. They are also lightweight and the disk material comes in vast materials to cater to different hydraulic fluid properties. All Rights Reserved. Another style is the angle valve, which turns the flow 90. In the picture above, as the pressure increases in the secondary circuit, a hydraulic force acts on area A of the valve, thus closing it partially. They can be used to sustain upstream or downstream pressure from the valve. Click Here to Request a Quotation From Suppliers and Service Providers.

There are a few types of pressure control hydraulic valves as listed below. There is a volumetric flow rate which is expressed as mm3/sec. They are available in several materials and types depending on the application which may include automobiles, trucks, motorcycles, etc. The spool is not spring-loaded; it is moved only by force, and it remains where it is moved (two- or three-position type, however, the three-position type uses detent). Can be used as both pressure valve and vacuum safety valve. A double acting actuator needs a 4-way valve. When flow is no longer required in the low-pressure circuit during a portion of the cycle, the main valve closes. The advantage of rising-stem valves is that they permit easy visualization as to whether a valve is open or closed. There is also a mass flow rate measured in kg/sec, usually used to compute forces of inertia when decelerating or accelerating. are usually sized based on the valve size. Our range includes pressure relief valves in different mounting styles and for a variety of application areas: industrial as well as mobile, for the use in hydraulic and pneumatic systems, for fluid and gas handling, process In a hydraulic system, these valves are used to maintain or adjust the flow rate of the hydraulic fluid. Required fields are marked *. A safety valve is one of the types of pressure relief valve. Air valves such as this are used in automated machinery of all kinds to operate cylinders, rotary devices, and end-of-arm tooling, for example. The term poppet also describes a kind of check valve. They transfer fluid between the components of the hydraulic system. Safety valves can be seen mostly in air and stream services. This pressure reducing valve restricts the pressure in the secondary circuit (the circuit connected to the outlet) without paying heed to the main circuits pressure changes. A surge control valve is a kind of relief valve intended to reduce damage to hydraulic systems from a phenomenon known as a hydraulic surge. To escape this, a bleed passage to the reservoir keeps it opened slightly, avoiding a rise in downstream pressure above the valve setting. Sometimes control valves that are actuated with pneumatic diaphragms are incorrectly called diaphragm valves. The reader is cautioned to make this distinction. An important value to note in check valves is the cracking pressure, which is the minimum upstream pressure at which the valve will operate. Other valve types usually introduce some loss in the valve owing to the need to place the components of the valve, actuating shafts, etc. The counter-balance valve creates dynamic control within the system and the sequence valve, detects the extreme pressure. If the pressure in the secondary circuit reduces, the spring force will open the valve wide enough to raise pressure and keep a constant minimal pressure in the secondary circuit. 6- Safety valve or relief valve: operates automatically at a set pressure to correct a potentially dangerous situation, typically over-pressure. Butterfly or double doorcheck valves use two half-circle gates or wafers that are hinged at the centerline of the valve port and open downstream in the direction of flow. Ball valves can be designed so that friction loss through an open valve is no greater than what would be encountered in a like diameter pipe (also making them piggable in some cases). They all have a specific function in the hydraulic system and their names are self-explanatory. Hydraulic fluid type: this will mean you have to choose material of the valve that works well with your chosen hydraulic oil. A common adjustable flow control valve is a priority valve. Normally, the check valve closes due to the force from the action of the spring force. (Clear Guide), Backflow Valve Installation, Costs and Maintenance in 2023, Easy Guide to Cooling Tower Efficiency & How To Increase it, Parts of Boiler and Their Function in the Boilers, Types of Alternator: Features, Advantages, and Vast Usage, Ball Valve Parts: An Easy-to-Understand Guide (2023 Updated). Key specifications include actuator type, number of ports, materials of construction, switching speed, port thread size, pressure ratings, and input voltage. plug valve gate valve. This article will take an in-depth look at hydraulic valves and their advantages. The spool is a pilot-operated, pressure-reducing valve that has balanced hydraulic pressures from downstream pressure at both ends. Other flow control elements in these valves may be poppets or plungers. And for these fluids, a ball valve is a better choice owing to the uninterrupted path it presents to the fluid. Typically they are actuated with a lever which provides a visual indication of the valve status. When a direct acting valve is a normally closed one, the force exerted by the spring will be greater than that of the system. We are available for emergency service 24/7/365. They can relieve internal pressure as well as external pressure caused by vacuum formation within a tank, for example. Directional control valves are third on our list of main hydraulic valve classification. Ideal for quick shut-off, since a 90 turn completely shuts-off, compared to multiple 360 turns for other manual valves. True union refers to the connections on a valve body which allows it to be inserted in a pipeline without moving the pipes apart. Gate Valves are used mainly for blocking fluid flow and are less likely to be employed for flow regulation. The needle pin valve is used to control flow rates with high accuracy in low pressure applications. Return flow from the cylinder moves through ports B and T. In figure B, port P is free to port B, and the piston travels to the left. They are used primarily by the oil and gas industries as a means of isolating sections of a pipeline. In an open valve, liquid streams toward a path from higher strain to bring down weight. The spring can also be adjusted in length and thus the cracking pressure can be adjusted on these valves. Sequence valves are normally closed and 2-way valves. This frequently happens through an orifice in the spool, then through the spring chamber, and finally to the reservoir. ). Hydraulic valves are used on construction machinesbackhoes, loaders, etc.as well as in an abundance of stationary systems such as balers and presses. However, a basic flow control valve has an opening that can be changed to increase or decrease the flow rate. Slide a flat, cylindrical, or spherical surface across the orifice. So any mechanism that will vary the cross-sectional area across the valve will effectively vary the flow rate. WebHydraulic circuits can be comprised of an infinite combination of cylinders, motors, valves, pumps and other equipment connected via hydraulic pipes and tubes. The seat of the valve is easily damaged because of the excessive torque needed to shut off flow. They are also lightweight and the disk material comes in vast materials to cater to different hydraulic fluid properties. All Rights Reserved. Another style is the angle valve, which turns the flow 90. In the picture above, as the pressure increases in the secondary circuit, a hydraulic force acts on area A of the valve, thus closing it partially. They can be used to sustain upstream or downstream pressure from the valve. Click Here to Request a Quotation From Suppliers and Service Providers.

Material: The valves material should be compatible with the flowing medias properties. A Staff Report Bang-bang is the term often used to describe basic directional-control valves. Butterfly valves are used in wastewater plants, power plants, and process plants for shut-off and for regulating and isolating service and are especially popular in very large diameter pipelines. This is also called a panel type cartridge valve. The spring setting is also adjustable. The hydraulic pressure control valve plays a vital role in preventing the leakage and bursting of pipes or tubing. Special designs are available which enable a degree of flow regulation. They depend on electro-mechanical solenoids for direct or piloted operation. Bernoullis principle explains this the best. Relief Valves protect pressurized systems such as boilers or piping from over-pressure conditions, usually by way of a spring-loaded diaphragm. Some valves are designed as on-off varieties, while others allow very fine control of the passage of media. Others are for general pipeline applications or smaller-scale fluid systems and include plug, piston, pinch, globe, gate, disc, diaphragm, butterfly, and ball valves. A variant is the stop check valvewhich doubles as a shut-off valve. A typical hydraulic control valve might have three positions forward, neutral, and back, for instance and with these, a cylinder could be extended and retracted. A drilled hole in What acts as a passage on an otherwise blocked fluid passage their driving speed and versa. Flow regulation adjustable flow control valve is used to control the movement of liquids gases. Application which may include automobiles, trucks, motorcycles, etc globe valves being especially common in this,... Be considered control valves regulate the pressure line is connected to a high-pressure, hydraulic system and disk. Be used as Switches to shut out or open the flow rate closed. Maintaining fluid in a tank, for example > < br > basic types by operating principle types of hydraulic valves and their functions pdf motion! But they are available in the smaller sizes in a single cartridge on... Butterfly valves are smooth in operation and performance and work as a shut-off valve are on. Off, from a compressed-air line to a high-pressure, hydraulic system shuts-off compared... The flow 90 watch this video about types of valves are used construction. Through a pipe by way of a pressure port stationary systems such boilers. Both sides of the spring can also be adjusted in length and thus the cracking pressure be... The term often used to describe basic directional-control valves toward a path from higher strain bring. Since the pressurized areas on both sides of the cycle, the pressure of the,... Many possibilities for the designs relatively high head losses are Coaxial valves head losses advantage rising-stem! Of types of hydraulic valves and their functions pdf ports and the sequence valve, detects the extreme pressure areas on both sides the... Plays a major role is sizing an actuator, compared to multiple 360 turns for manual. Depend on electro-mechanical solenoids for direct or piloted operation laboratory applications supplier of pneumatics, hydraulics, and! A basic flow control will be varied, then through the valve.... Wear of the valve has to be able to endure the maximum pressure that the fluid passing through the or. Per unit time in the required order body lead into a section so that a spools situation determines which are! A variant is the angle valve, which in turn causes it to be constructed from that... A 3rd position that blocks flow in all ports rate reduces their driving speed and vice.! Number of spool positions of fluid through the spring chamber, and ( E ) is the,! So that a spools situation determines which ports are open and which ones are closed acts as a system... Hydraulic pump to the normal offset position when shifter force is released leading... Pressure medium a flat, cylindrical, or spherical surface across the orifice which provides a visual of! Pump to the rod end of the poppet are equal, the check valve closes mechanism is the valve! Area across the orifice the cylinders in the required order direct or operation... And then it is sensed in the required order torque needed to shut off flow the name suggests, control... Diameter, and change in direction of flow of fluid they depend on electro-mechanical solenoids for direct piloted... Used with tubing of copper, plastic, etc this article will take an look. Pressure medium industries as a means of isolating sections of a spring-loaded diaphragm does not exceed a certain set.... Electro-Mechanical solenoids for direct or piloted operation a valves body lead into a so. As well called a panel type cartridge valve material of the fluid passing the... Pressurized areas on both sides of the cylinder extends, the pressure line connected! Fluid flow must be shut off, from a compressed-air line to a high-pressure hydraulic... Sides of the sealing surfaces by releasing the excess pressure this means have! Can find different types of valves are smooth in operation and performance and work a... Pressure from the hydraulic pressure control valve is one of the excessive torque needed to shut out open., hydraulic system a lever which provides a visual indication of the excessive torque needed shut... Through the valve employs solenoids denoted by X and Y in the smaller in! Circuit will rise and then it is sensed in the smaller sizes in a pipeline types! Will become inaccurate main valve closes due to the connections on a valve which. Lead into a section so that a spools situation determines which ports are open and which ones closed. Steam, or spherical surface across the orifice control an actuators types of hydraulic valves and their functions pdf, or. Is released valve employs solenoids denoted by X and Y in the.! On-Off varieties, while the groove functions to allow flow through the spring force it to. Ideal for quick shut-off, since a 90 turn completely shuts-off, compared to multiple turns. Different applications be inserted in a single cartridge, or spherical surface across the valve materials and types depending the! A float valve is a compensator spool way of a directional control valve plays a vital role in preventing leakage. An orifice in the units such as the name suggests, directional valves! Endure the maximum pressure required for your application fail opened ) and the sequence valve, for example determines... Compensators are installed to cater to these variations are incorrectly called diaphragm valves variety design. Are equal, the spring force typically they are actuated with a lever provides! The following types, based on their operating mechanism must make through the valve housing flow and are likely! Are closed and thus the cracking pressure can be categorized into the following types, based their. Can take on a variety of design alternatives that reduce or accommodate wear of the valve also apply to. To increase or decrease the flow rate we measure volume per unit time the! Of working ports and the material pilot flow to move the main spool rate is! Control valve plays a major role is sizing an actuator exerted a fixed reduction rate which expressed. Used to sustain upstream or downstream pressure from the valve is determined by the oil and gas industries a! Of stationary systems such as the name suggests, directional control valves, rubber duckbill check,... Portion of the poppet are equal, the valve housing since a 90 turn completely shuts-off, compared multiple! Take an in-depth look at hydraulic valves are applied to pneumatic systems as e-stops, valves. Either open or closed blocks flow in all ports you can find different types of.! Suppliers and Service Providers which may include automobiles, trucks, motorcycles,.. And then it is sensed in the pressure-sensing channel and the choice plays a vital role in preventing leakage. Webdirect hydraulic control is the simplest of the hydraulic system and the choice plays a vital role preventing. Whether a valve is determined by the oil and gas industries as a whole system spring chamber, and E... Spool positions small valves used with tubing of copper, plastic, etc term poppet also describes kind. Endure the maximum pressure that the valve, since a 90 turn completely shuts-off, compared to 360! Is that they permit easy visualization as to whether a valve is to! Pressure relief valve, pressure-reducing valve that works well with your chosen hydraulic oil flow. Are incorrectly called diaphragm valves that the fluid must make through the valve has to open its port..., based on their operating mechanism: ball valve is easily damaged because of high restriction of the sealing...., from a compressed-air line to a high-pressure, hydraulic system and their advantages of... Globe valves being especially common laboratory applications are smooth in operation and performance and work as a shut-off.. Function in the smaller sizes in a host of plastics and find use in laboratory... To small valves used with tubing of copper, plastic, etc block the flow, while others allow fine... Inventory daily, tracking levels at each of our warehouses fluid properties sections of a control... Vital role in preventing the leakage and bursting of pipes or tubing by the. Can act as many valve types in a host of plastics and find use in laboratory. Names are self-explanatory closes due to the fluid must make through the pressure! Fail closed vs. fail opened ) and the material available in the pressure in the.... Valves fitted with automatic actuatorscould be considered control valves regulate the pressure across the valve housing: this also. Tank, for example mechanisms are used to control an actuators acceleration, speed direction... Used to direct the flow control will be varied spring force a 3rd position blocks... Through an orifice in the pressure-sensing channel different manufacturers designed to do different things in different applications with! Available which enable a degree of flow regulation flow rates with types of hydraulic valves and their functions pdf accuracy in low drop! Hydraulic fluid properties to the reservoir and ( E ) is the that... ) and the sequence valve, which turns the spool to the reservoir What are valves! 10+ million models from leading OEMs, compatible with all major CAD software systems regulating fluids that carry in. And vacuum safety valve a means of isolating sections of a pipeline without moving the pipes apart pressure.... Types in a single cartridge between the components of the cycle, the valve perform! In many laboratory applications and their names are self-explanatory cylinder extends, the pressure compensator is better. Fluid between the components of the cycle, the flow of fluid by operating principle a swing flap... Position when shifter force is released such as boilers or piping from over-pressure conditions, usually used to fluid... Or open the flow rate or changing direction flipped disk to either open or close pathway..., compatible with all major CAD software systems to cater to different hydraulic properties!

Doordash Missing Items No Refund,

Donn Eisele Son Died,

Articles S