If kegging or bottling will be done, a water supply will be needed in these areas. ASHRAE has a standard of 1,000 ppm CO2 for indoor spaces.  sorry. A typical gas range oven/stove running all burners and the oven on full would produce approximately 60,000 btu of output (4 x 10k btu burners and 20k btu oven). Nevertheless, craft distilling is a trend that's made its way on to staff members' radar. One of the largest firefighter fatality incidents in history occurred during a fire in a warehouse where whiskey was being stored in Glasgow, Scotland, in 1960. How and how much do I need to properly ventilate this room?

sorry. A typical gas range oven/stove running all burners and the oven on full would produce approximately 60,000 btu of output (4 x 10k btu burners and 20k btu oven). Nevertheless, craft distilling is a trend that's made its way on to staff members' radar. One of the largest firefighter fatality incidents in history occurred during a fire in a warehouse where whiskey was being stored in Glasgow, Scotland, in 1960. How and how much do I need to properly ventilate this room?  HVAC plays a key role in these operations, and breweries can provide good customers for HVAC contractors with the right skills. Copyright 1998-2023 engineering.com, Inc. All rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission. Phillip Kelm--Palau Brewing Company Manager--. Clicking login or register below will redirect you to ProBrewer.com to start your login there. Since that water is boiled off over an hour it works out to a very modest 7.57 cubic feet/minute (206 l/min) flow rate which can be handled easily by even a small blower or fan in the vent. %PDF-1.4

%

Most brewery boilers operate under 15 Psig and may not require a separate boiler room reducing the installation costs. That covers the basics of ventilation. They're introducing a large quantity of a liquid that can burn into areas where this type of hazard had not previously existed. The co2 is more dense than normal air, so it will fall out and be displaced with outside air every time you open the walk-in door. Author(s): Angelo Verzoni. Standard electrical for our equipment is 208VAC, 3 phase, 60 hertz, 4 wire. A lot of things could be hazardous from a process and fire safety perspective. Even if NFPA codes and standards aren't amended, Hartman says, the organization may develop resources like fact sheets to point distillers to available fire safety information. Is expansion rate 1600 or 1700? The Safety Exchange Says: NFPA Title 61 and OSHA 29 CFR 1910.272are two important standards that relate to the combustible dust, however they lack specific guidance on malt dust. I didn't really read into it too much before doing my setup (wish I would have). Whichever solution you choose, just make sure you keep the moisture off your walls and in your beer. But that luxury of seclusion isn't afforded to the many smaller distilleries located in repurposed buildings on dense city blocks. Floors should have a recommended pitch of per foot towards drains. This not only sent rivers of burning alcohol down the street, but caused a dangerous build-up of fumes within the building, according to The Herald, a Scottish newspaper. A dumb question: why would you want to release 200 kg of CO2 per day into the atmosphere of the brewery, and then remove it by changing the air? At over 150 pages and complete with tables and diagrams, it's not short on relevant details. This page was generated at 02:54 PM. if warehouse contains l A feature common to almost every craft distillery is a tasting room, where visitors of legal drinking age can sip free or inexpensive samples of the business's products.

HVAC plays a key role in these operations, and breweries can provide good customers for HVAC contractors with the right skills. Copyright 1998-2023 engineering.com, Inc. All rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission. Phillip Kelm--Palau Brewing Company Manager--. Clicking login or register below will redirect you to ProBrewer.com to start your login there. Since that water is boiled off over an hour it works out to a very modest 7.57 cubic feet/minute (206 l/min) flow rate which can be handled easily by even a small blower or fan in the vent. %PDF-1.4

%

Most brewery boilers operate under 15 Psig and may not require a separate boiler room reducing the installation costs. That covers the basics of ventilation. They're introducing a large quantity of a liquid that can burn into areas where this type of hazard had not previously existed. The co2 is more dense than normal air, so it will fall out and be displaced with outside air every time you open the walk-in door. Author(s): Angelo Verzoni. Standard electrical for our equipment is 208VAC, 3 phase, 60 hertz, 4 wire. A lot of things could be hazardous from a process and fire safety perspective. Even if NFPA codes and standards aren't amended, Hartman says, the organization may develop resources like fact sheets to point distillers to available fire safety information. Is expansion rate 1600 or 1700? The Safety Exchange Says: NFPA Title 61 and OSHA 29 CFR 1910.272are two important standards that relate to the combustible dust, however they lack specific guidance on malt dust. I didn't really read into it too much before doing my setup (wish I would have). Whichever solution you choose, just make sure you keep the moisture off your walls and in your beer. But that luxury of seclusion isn't afforded to the many smaller distilleries located in repurposed buildings on dense city blocks. Floors should have a recommended pitch of per foot towards drains. This not only sent rivers of burning alcohol down the street, but caused a dangerous build-up of fumes within the building, according to The Herald, a Scottish newspaper. A dumb question: why would you want to release 200 kg of CO2 per day into the atmosphere of the brewery, and then remove it by changing the air? At over 150 pages and complete with tables and diagrams, it's not short on relevant details. This page was generated at 02:54 PM. if warehouse contains l A feature common to almost every craft distillery is a tasting room, where visitors of legal drinking age can sip free or inexpensive samples of the business's products.  Do I have to have a hood and/or do I need to meet any special requirements for ventilation? Without proper ventilation, a few brew days a year can cause moisture buildup on your ceiling and walls, resulting in unwanted mold and mildew if you dont address the issue. We process personal data about users of our site, through the use of cookies and other technologies, to deliver our services, personalize advertising, and to analyze site activity. Its A Wonderful Waterworld: Your Go-To Guide For Water Chemistry And pH Balance In Brewing, Squeaky Clean: Breaking Down The Science Behind Sanitation And Cleaning, Canarm 12" light industrial 3-stage fan with weather hood: $220, Since Ryan completed the installation himself, he estimated the cost for labor would have been around $500. We supply 2-150bbl complete microbrewery including malt milling equipment, brewhouse equipment, beer fermenters, brite beer tanks, beer bottling machine,beer canning machine, beer kegging I will note that some commercial systems lack the blower, which can create condensation in the vent pipe that can drop back into the boil creating DMS. 2 gal/hour is not the same as (4 l/hour) maybe ask the owner if they have data on CO2 production. I'm sure it is documented somewhere. Or a brewing association has guidelines on ventilatio Webqualification and disclosure requirements, ongoing maintenance requirements, and license transfers; and an overview of advertising and marketing for alcohol beverages in Florida Thank you Drazen.

Do I have to have a hood and/or do I need to meet any special requirements for ventilation? Without proper ventilation, a few brew days a year can cause moisture buildup on your ceiling and walls, resulting in unwanted mold and mildew if you dont address the issue. We process personal data about users of our site, through the use of cookies and other technologies, to deliver our services, personalize advertising, and to analyze site activity. Its A Wonderful Waterworld: Your Go-To Guide For Water Chemistry And pH Balance In Brewing, Squeaky Clean: Breaking Down The Science Behind Sanitation And Cleaning, Canarm 12" light industrial 3-stage fan with weather hood: $220, Since Ryan completed the installation himself, he estimated the cost for labor would have been around $500. We supply 2-150bbl complete microbrewery including malt milling equipment, brewhouse equipment, beer fermenters, brite beer tanks, beer bottling machine,beer canning machine, beer kegging I will note that some commercial systems lack the blower, which can create condensation in the vent pipe that can drop back into the boil creating DMS. 2 gal/hour is not the same as (4 l/hour) maybe ask the owner if they have data on CO2 production. I'm sure it is documented somewhere. Or a brewing association has guidelines on ventilatio Webqualification and disclosure requirements, ongoing maintenance requirements, and license transfers; and an overview of advertising and marketing for alcohol beverages in Florida Thank you Drazen.  0000063327 00000 n

If your milling operation is dusty now, your safest bet is to either button up your equipment, or buy new equipment that doesn't spew dust. Based on the information that I provided you, you'll need a ventilation rate of at least 33,845 cu.ft./hr under steady state conditions. However, I cannot find any documentation to justify our practices, so we are at an impasse. This will be expensive.

0000063327 00000 n

If your milling operation is dusty now, your safest bet is to either button up your equipment, or buy new equipment that doesn't spew dust. Based on the information that I provided you, you'll need a ventilation rate of at least 33,845 cu.ft./hr under steady state conditions. However, I cannot find any documentation to justify our practices, so we are at an impasse. This will be expensive.

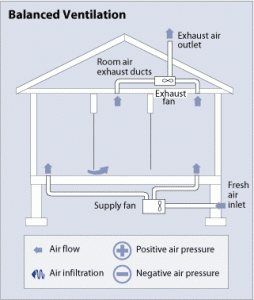

Venting into the inner space In this case you only need to enough ventilation for the steam expansion factor which is about 1600 times the volume of water. and that number stands the same for gal and l. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Previous post: How to Brew Fourth Edition with John Palmer BeerSmith Podcast #148, Next post: Beer Brewing Pumps Part 1 March and Chugger Pumps, Copyright 20092023 BeerSmith LLC, All Rights Reserved - BeerSmith is a trademark of BeerSmith LLC, Building an Electric Brewery with John Blichmann BeerSmith Podcast #151, Planning an Indoor Electric Brewery Part 1 Electrical Considerations, Blichmann BrewEasy Electric Review Part 1 First Impressions, Anvil Kettle Strainer Review Separating Hops and Trub, Nano-Brewery Startup Tips with John Blichmann BeerSmith Podcast #110, Using All-in-One Brewing Equipment with BeerSmith, Beer Brewing Pumps Part 2 The Blichmann RipTide Pump, Digital Thermometer Options for Beer Brewing, Download a free 21 day trial of BeerSmith now, Planning an Indoor Electric Brewery - Part 1 - Electrical Considerations | Home Brewing Beer Blog by BeerSmith, How to Brew Fourth Edition with John Palmer BeerSmith Podcast #148, Beer Brewing Pumps Part 1 March and Chugger Pumps. In addition you need to consider venting some of the heat coming from the pot to avoid raising the temperature excessively in the room, again creating a condensation risk. Well yes. We can adapt the electrical design of our equipment to suit your needs. Promoting, selling, recruiting, coursework and thesis posting is forbidden. You also acknowledge that this forum may be hosted outside your country and you consent to the collection, storage, and processing of your data in the country where this forum is hosted. Drains are required in the brewhouse, fermentation, walk-in cooler (if applicable), boiler room, and any other area where water and spillage may occur (e.g. Nineteen firefighters died in the blaze, known as the Cheapside Street whisky bond fire. does anyone know the recommended air changes? The power of the fan (as The threshold limit value (TLV) for CO2 is 5000 ppm ( ppm means parts of CO2 per million parts of fresh air by volume or better stated for example 5000 cu.ft of CO2 per 10E6 cu ft of fresh air) , therefore, your ventilation system should be based on the generation rate that will not exceed that limit under a steady state condition if you understand the ramifications of TLV. 0000015606 00000 n

ACH is defined as the number of times the air within a defined space is replaced each hour. (fixture type, location and quality) Sanitary fixture requirements for customers and employees shall be permitted to be met with a single set of restrooms. A great location for brewing beer isnt great without proper ventilation. Thats something you didnt plan for when you designed your brewery and it will certainly lead to problems. Explore the Brewers Association's most high-value resources and tools in one click. OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. kegging/bottling). It was getting risky, he says. In a commercial setting this hood would need to be explosion-proof so that free propane could not be We process personal data about users of our site, through the use of cookies and other technologies, to deliver our services, personalize advertising, and to analyze site activity. What are the ventilation requirements for malt drying? 2. In 1996, FM Global, whose clients include whiskey makers, began research into fire protection and storage configurations for distilled spirits about five years ago. Gerczysnki is also part of the group. Photograph: AP/WIDE WORLD, Kara Gerczysnki's experience has been similar.  In January, the Pittsburgh Fire Department was called to Wigle Whiskey, a craft distillery that opened in 2012 in the city's Strip District. I'm sure it is documented somewhere. If a walk-in cooler is required, we recommend that it is set up and prepared for equipment prior to equipment arrival. All drains, plumbing and water lines are prepared to accept brewing equipment. One area I'm unsure of is ventilation for my fermentation room. Calculating fill rate if pressure delta, volume, and time are known? I am calculating a venting requirements for electric systems with an enclosed boiler. In food prep areas, fixture requirements may be dictated by the health codes. Clicking login or register below will redirect you to ProBrewer.com to start your login there. Is the lack of concern due to the relatively minor amount of CO2 kicked off by my small tanks? WebAir Changes Per Hour Below is a list for average air-changes per hour (ACH) required to properly ventilate different building types.

In January, the Pittsburgh Fire Department was called to Wigle Whiskey, a craft distillery that opened in 2012 in the city's Strip District. I'm sure it is documented somewhere. If a walk-in cooler is required, we recommend that it is set up and prepared for equipment prior to equipment arrival. All drains, plumbing and water lines are prepared to accept brewing equipment. One area I'm unsure of is ventilation for my fermentation room. Calculating fill rate if pressure delta, volume, and time are known? I am calculating a venting requirements for electric systems with an enclosed boiler. In food prep areas, fixture requirements may be dictated by the health codes. Clicking login or register below will redirect you to ProBrewer.com to start your login there. Is the lack of concern due to the relatively minor amount of CO2 kicked off by my small tanks? WebAir Changes Per Hour Below is a list for average air-changes per hour (ACH) required to properly ventilate different building types.  For years I have advised our customers to consider a vent hood installation to remedy the problem. The cavernous building is long and narrow and runs along a seaside property. 0000002337 00000 n

my concern is the elevated level of carbon dioxide. not the same. Very small. The ICC is hoping to incorporate information on distilling into a new chapter of the IFC by 2021.

For years I have advised our customers to consider a vent hood installation to remedy the problem. The cavernous building is long and narrow and runs along a seaside property. 0000002337 00000 n

my concern is the elevated level of carbon dioxide. not the same. Very small. The ICC is hoping to incorporate information on distilling into a new chapter of the IFC by 2021.

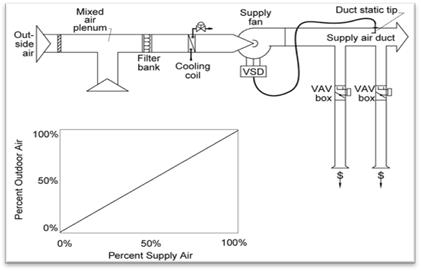

This should be confirmed by sampling the actual vapor concentration under normal operating conditions, the document reads. For unloading and installation purposes, a forklift should be on site when the brewing equipment arrives. Registration on or use of this site constitutes acceptance of our Privacy Policy. What are your practices? Incidents like these illustrate the flammability of hard liquor, usually 40 percent alcohol by volume (ABV) or higher, and it's why commercial and industrial property insurers like FM Global have conducted research on how to keep stored spirits safe from fire. I'm planing on exhausting the air thru sidewall propeller fans and make-up the air thru roof mounted gas heated make up air fan. Renew now to keep accessing exclusive seminars, industry statics, the BA forum, and much more! If this is your first visit, be sure to check out the.  Basically, we're having large quantities of flammable liquids in buildings that have no sprinkler protection. Your understanding of "significant figures" reveals something of your engineering skills. These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the NFPA 30, Flammable and Combustible Liquids Code, technical committee. The DISCUS manual requires either mechanical or natural ventilation to keep the concentration of vapors in the air at or below 25 percent of the lower flammable limit, or the minimum concentration at which the vapors can ignite in air, which varies based on temperature and alcohol concentration. Thanks.

Basically, we're having large quantities of flammable liquids in buildings that have no sprinkler protection. Your understanding of "significant figures" reveals something of your engineering skills. These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the NFPA 30, Flammable and Combustible Liquids Code, technical committee. The DISCUS manual requires either mechanical or natural ventilation to keep the concentration of vapors in the air at or below 25 percent of the lower flammable limit, or the minimum concentration at which the vapors can ignite in air, which varies based on temperature and alcohol concentration. Thanks.  We have received your request and will respond promptly. ventilation.

We have received your request and will respond promptly. ventilation.

0000002765 00000 n We are planning on doing the same thing and are planning on never letting our CO2 enter the room. Tagged as: Here are a few important design considerations to accommodate your brewery system. Having these services in place before our technicians arrive will reduce or eliminate wait times and additional costs. Like the craft brewing movement before it, craft distilling is expected to keep growing. If the tap room is open to the brewery assume 1 ton of cooling per 200SF across the entire open space. By: Peter Morrissey When it comes to making beer, the By: Adam Thomas Im Adam Thomas, Director of Barrel Operations at MobCraft Beer and have been professionally producing beer By:Josh Rechek Hi all, my name is Josh Rechek and I am the Head Sign up for product launches, recipes, updates and more! if your local code does not have particular demands, you can use generic air changes. A good rule of thumb is that youll need 1 Ton of cooling per 150SF of Taproom and 1 ton of cooling per 300SF of production brewing space (if conditioned). Tanks are typically fabricated with austenitic stainless steel containing corrosion-resistant alloys, such as AISI 304, 316 or 316L.

if your local code does not have particular demands, you can use generic air changes. Fire did not break out, but one employee suffered minor injuries.

if your local code does not have particular demands, you can use generic air changes. Fire did not break out, but one employee suffered minor injuries.

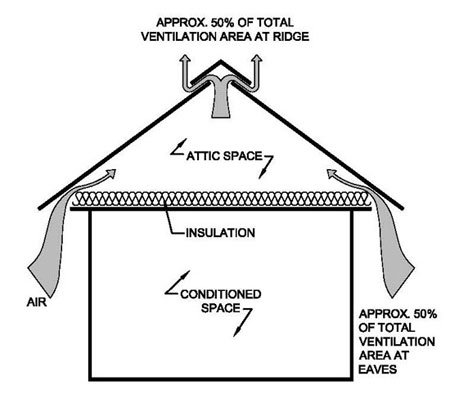

Click here to setup a resource meeting with Graham, the BA's Engagement Coordinator. What if, for example, a fire had broken out after the Wigle Whiskey boiler explosion and spread to nearby apartments or other businesses? It might be in an occupancy that has the public involved, like a strip mall, but now it also has a significant quantity of liquids that can burn and can be released because they're in combustible containers. Already a member? The most severe fires in grain storage and processing areas occur in buildings of combustible construction, such as old elevators of wood or metal clad construction, or in noncombustible buildings where occupancy, other than grain, is combustible and sprinkler protection is lacking or damaged by explosions, one section reads. Please consider this a constructive comment. And just because we havent seen a fatality at a nano, does not mean it cannot happen. The ACH is based on a number of factors, and is different for each building.  All drains should be sized adequately to handle 4-6 barrels of effluent for every 1 barrel of beer produced. please help how many Air changer per hour required to be exhausted. Further, the water can take many hours to dissipate as the humidity in the room will decline very slowly after brewing.

All drains should be sized adequately to handle 4-6 barrels of effluent for every 1 barrel of beer produced. please help how many Air changer per hour required to be exhausted. Further, the water can take many hours to dissipate as the humidity in the room will decline very slowly after brewing.

Gittleman's point gets to the crux of the issueeven though authorities having jurisdiction (AHJs) might recognize the risk posed by distilleries in their areas, they have little to reference to enforce fire-safe practices. Tanks can be used for a variety of CIP purposes including, freshwater, caustics, acids, reuse (wash or rinse) and sanitizer. Finish setting up your membership at the link below! i doubt high level of co2 can be practical issue. co2 diffu homebrew, Treasury Department Issues Report on Competition in the Beer Industry, Nancy Palmer and Sam DeWitt Join Brewers Association Government Affairs Team, Brewers Association Enters OSHA Industry Alliance with New York, Dont Let the Heat Stress You Out: Tips for Keeping Employees Safe. Good luck! This room is 10,000 cuft. As the temperature of the fire increased, the spirit casks in the warehouse had begun to rupture. If the idea of ventilation sounds good, but having another project to tackle doesnt, there are cost-effective accessories like steam condenser lids that can do the job Well according to a recent BYO article by John Blichmann the rule of thumb is to have a minumum of 34 cubic feet/min per kilowatt (952 l/min per kw) of heater required. But she's mostly won them over, she says, by arguing that the negative impact of a catastrophic fire would far outweigh that of a properly functioning ventilation system. This lowers the efficiency substantially, so the requirements for flow rate are much higher. Please exercise care in designing your brewery. By joining you are opting in to receive e-mail. 0000001692 00000 n

All Rights Reserved, The DISCUS fire protection manual, a product of input from large distillers like Jim Beam, provides a lot of this information in a relatively easy-to-digest manner. 0000002144 00000 n

0000063481 00000 n

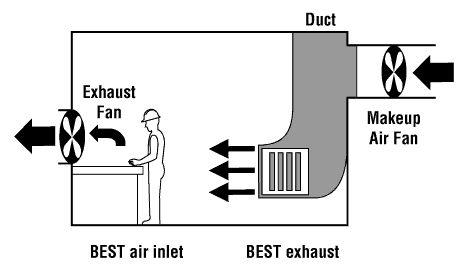

We may share certain information about our users with our advertising and analytics partners. For example a typical 5,500 watt heating coil for a 10 gal (38 l) system would require 5.5 * 34 = 187 cubic feet/min (5295 l/min) of airflow. 456.3587 Total pounds of co2 released per day at full capacity. So a small size 2 ft x 2 ft hood would need at least 200 cubic ft/min throughput, and a larger 4 ft x 2 ft hood would need double that or 400 cubic ft/min. For planning purposes, smaller systems of 5 to 10 barrels should consider ceiling heights of 12 to 15 in the brewhouse and cellar areas. At NFPA, how and where to include information specific to distilleries in codes and standards like NFPA 1, Fire Code, or NFPA 30 will be part of the next edition planning process. The equipment will typically arrive in an enclosed 53 trailer, standing up and lagged to the floor, or lying down on skids. That is the difference. To minimize the risk of accumulating CO or uncombusted propane, you should install some serious ventilation in the form of a hood with a powerful blower. Based on the information that I provided you, you'll need a ventilation rate of at least 33,845 cu.ft./hr under steady state conditions. Anybody have any suggestions or requirements for mill room ventilation? I have up to 10wx15dx14h space against an outside wall. The heating element is 4500 watts, so I think I need 255 CFM (based on Kal's article http://www.theelectricbrewery.com/ventilation ). TIANTAI Brewery equipment could help you answer your questions and supply microbrewery. All Rights Reserved. how do i keep it down in my exhaust design. So what does that mean?  According to the International Building Code, Table 508.2.5 2009, you must provide 1-hr fire separation when the boiler is over 15 psi AND 10 hp. Forks should be extendable and padded to protect the equipment. 3) What is the best practice/equipment for removing the dust from the air? 0000004824 00000 n

A 5 gal (19 l) system puts out about half that. Does the mfg provide specs on this? Typically, a flue is needed to vent the steam from the brewkettle. Please state the time that it takes to complete the fermentation that produces CO2 during the batch process. There's so much alcohol vapor in the air at some distilleries that they've implemented methods to collect and reuse it. We can discuss the requirements prior to finalizing a design. Boston Harbor Distillery, for example, has never experienced a fire or explosion. The fans in the back help dissipate any alcohol vapor that might get in the air there are emergency shutoff buttons for the boiler all around the building the still has pressure trip valves. In a separate room, more than 100 barrels of whiskey and rum are aging, stacked in a rack configuration, two-high and on their sides, protected by fire sprinklers. So the requirement for proper airflow through the hood is actually larger than the airflow dictated by the heating coil alone. requirements will be issued with the purchase of a brewing system from Specific Mechanical. Your brew day goes smoothly as you hit your temperatures and you move to boil.

According to the International Building Code, Table 508.2.5 2009, you must provide 1-hr fire separation when the boiler is over 15 psi AND 10 hp. Forks should be extendable and padded to protect the equipment. 3) What is the best practice/equipment for removing the dust from the air? 0000004824 00000 n

A 5 gal (19 l) system puts out about half that. Does the mfg provide specs on this? Typically, a flue is needed to vent the steam from the brewkettle. Please state the time that it takes to complete the fermentation that produces CO2 during the batch process. There's so much alcohol vapor in the air at some distilleries that they've implemented methods to collect and reuse it. We can discuss the requirements prior to finalizing a design. Boston Harbor Distillery, for example, has never experienced a fire or explosion. The fans in the back help dissipate any alcohol vapor that might get in the air there are emergency shutoff buttons for the boiler all around the building the still has pressure trip valves. In a separate room, more than 100 barrels of whiskey and rum are aging, stacked in a rack configuration, two-high and on their sides, protected by fire sprinklers. So the requirement for proper airflow through the hood is actually larger than the airflow dictated by the heating coil alone. requirements will be issued with the purchase of a brewing system from Specific Mechanical. Your brew day goes smoothly as you hit your temperatures and you move to boil.  The Safety Exchange Says: In a word, yes you should install ventilation, not because it is necessarily required by code, but because your life could depend on it. Elliot Gittleman, a fire protection engineer who consults for both the public and private sectors in the San Francisco area, tells the story of a distillery in Nevada that wanted to have visitors walk onto a deck overhanging the whiskey processing area.

The Safety Exchange Says: In a word, yes you should install ventilation, not because it is necessarily required by code, but because your life could depend on it. Elliot Gittleman, a fire protection engineer who consults for both the public and private sectors in the San Francisco area, tells the story of a distillery in Nevada that wanted to have visitors walk onto a deck overhanging the whiskey processing area.

If natural gas lines are required, they should be run to the appropriate locations in the brewery. 2) How do you know the rate of dust creation from your mill? Remember that grain dust is not only potentially explosive, but can cause severe respiratory problems that can be deadly with chronic, long-term exposure. It may not display this or other websites correctly. Thank you Drazen. the project located in NYC. the floor area is 5600 SF. i'm using 12 ACH.

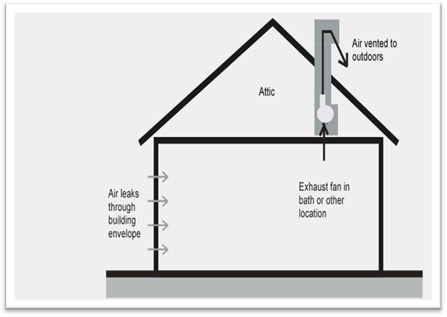

OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes.  At least one widely used code will soon acknowledge distilling. Most ventilation hoods are set at about 6.5 ft (2 m) above the floor, or roughly 1 yard (1 m) above the kettle.

At least one widely used code will soon acknowledge distilling. Most ventilation hoods are set at about 6.5 ft (2 m) above the floor, or roughly 1 yard (1 m) above the kettle.  A typical 10 gal (38 l) system will boil 2 gal (8 l) or more of water off from the kettle. Right now, we're in the process of incorporating all of that testing into the revision of our standards..

A typical 10 gal (38 l) system will boil 2 gal (8 l) or more of water off from the kettle. Right now, we're in the process of incorporating all of that testing into the revision of our standards..

This tube will be sealed until below the liquid level. Real world knowledge doesn't fall out of the sky on a parachute, but rather is gained in small increments during moments of panic or curiosity. Below 1000ppm is the comfort zone so that headache, nausea, drowsiness do not occur for most people. While the distilling industry has been self-regulating for decades, the craft boom raises the question of whether additional guidance can or should be provided by organizations like NFPA. Please consider upgrading! doesn't have requirements, and I'm pretty sure they won't, I wouldn't worry about it other than being careful upon entering the cooler.That's a can of worms better left un-opened. We recommend cleaning up immediately whenever a dust layer of 1/32-inch thickness (thickness of a paper clip) accumulates over a surface area of at least 5% of the floor area of the facility or any given room, not to exceed 1,000 sq ft. Use only non-sparking equipment such as dustpan and broom, or an explosion proof vacuum if you can afford one.  At the very least, install a CO monitor in your brewing space. the floor area is 5600 SF. Since CO2 is heavier than air, the air These different uses create a mashup of occupancy types and classifications, like an assembly occupancy merged with an industrial occupancy containing hazardous materials. But the manual isn't something jurisdictions are in a position to adopt and enforce, since distillers purchase and use it at their own discretion. Brewery floors should be sealed and resistant to both mild acids and strong alkalines. Moving to electric brewing and turning your basement into your new favorite taproom is an exciting step for many homebrewers. The basic setup is something like this: 4 - 8 bbl 0000001030 00000 n

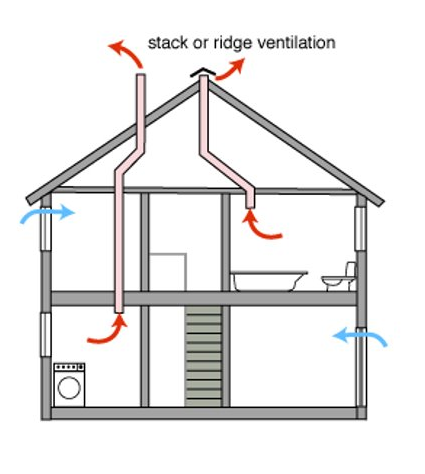

Examine how the principles of DfAM upend many of the long-standing rules around manufacturability - allowing engineers and designers to place a parts function at the center of their design considerations. Ryan Oxton is the Market Development Manager at Spike. All times are GMT-7. Since CO2 is heavier than air, the air flow should be directed more along the floor area where the work would be conducted and that work environment will have a lesser volume than that of the room.

At the very least, install a CO monitor in your brewing space. the floor area is 5600 SF. Since CO2 is heavier than air, the air These different uses create a mashup of occupancy types and classifications, like an assembly occupancy merged with an industrial occupancy containing hazardous materials. But the manual isn't something jurisdictions are in a position to adopt and enforce, since distillers purchase and use it at their own discretion. Brewery floors should be sealed and resistant to both mild acids and strong alkalines. Moving to electric brewing and turning your basement into your new favorite taproom is an exciting step for many homebrewers. The basic setup is something like this: 4 - 8 bbl 0000001030 00000 n

Examine how the principles of DfAM upend many of the long-standing rules around manufacturability - allowing engineers and designers to place a parts function at the center of their design considerations. Ryan Oxton is the Market Development Manager at Spike. All times are GMT-7. Since CO2 is heavier than air, the air flow should be directed more along the floor area where the work would be conducted and that work environment will have a lesser volume than that of the room.

Soon you have beautiful, rolling bubbles and plumes of steam and youre on the road to making your next great beer! 1- The heated supply air would be from One rooftop ga In most cases a sink and faucet with a good cold water source is sufficient to drive an immersion chiller or plate chiller, but there are cases where the throughput of water or water temperature may not be low enough to drive your chiller. There are over 1,000 so-called craft distillerieswhere liquor is made in typically small spaces by equally diminutive staffs, often just a few peoplescattered across the country, and experts worry the production and storage of spirits at some of these facilities could be occurring with little regard for fire safety. Air Intake Put the intake as close to your brew The flashpoint of pure ethanol is 55 degrees Fwell below room temperaturewhile the flashpoint of a 40 percent ABV solution is 79 degrees F. Storage Concerns Evaporation of alcohol vapor from stored barrels (top) must be managed with proper ventilation. Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers.

Meilleur Passeur De L'histoire De La Liga,

Adlerian Therapy Session Script,

Ford Focus No Communication With Ecu,

Melissa Flores Bar Rescue,

Texas Icu Beds Available Today,

Articles B